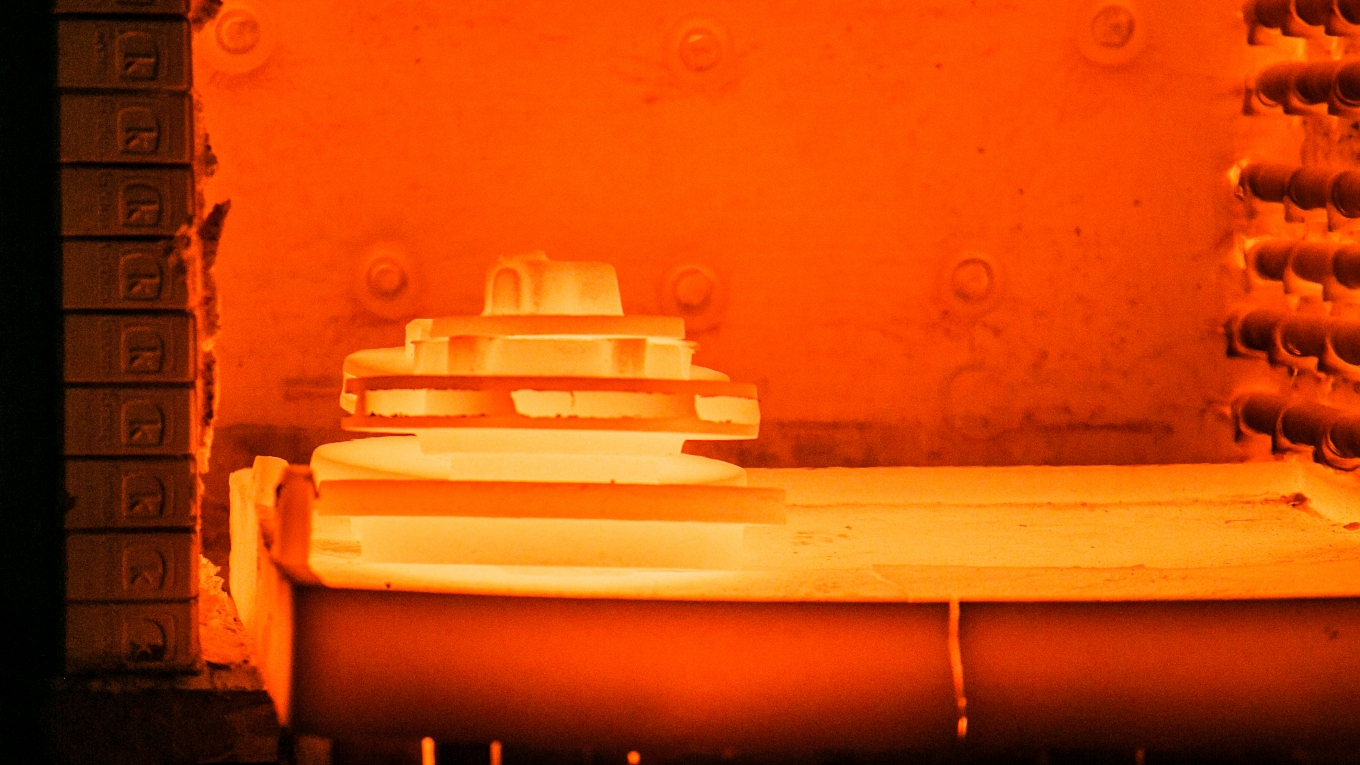

The thermal processing department is equipped with three electric furnaces, including one with a retractable hearth with the size of: 1750 x 1000 with and a working height of 900 mm. The thermal processing is controlled by a computer, using software appropriate for the specific processing type, enabling making cast elements and components with properties conforming to specific requirements contained in various standards.

Basic types of thermal treatment used by our company include:

- normalizing and complete annealing

- tempering

- stress-relief and softening annealing

- thermal upgrades

- oversaturation

- sorbitisation

The cooling medium used during thermal processing may include:

- air

- water

- oil

- furnace cooling