MATERIAŁY DO POBRANIA

![]() Katalog

Katalog

![]() 2D

2D

![]() 3D

3D

DATA PUBLIKACJI - 2017-11-07

TYPICAL APPLICATIONS

- mining – main and auxiliary dewatering,

- industrial systems,

- technological processes,

- pressure boosting,

- pumping of pure or mechanically contaminated water with solids with the grain size of up to 2 mm,

- coal, copper, salt mines and others.

KEY ADVANTAGES

- new improved design with increased efficiency

- long life ensured by the use of state-of-the-art corrosion and erosion resistant materials (saltresistant workmanship),

- special material execution DUPLEX especially resistant to difficult conditions,

- possibility to use an electronic system of the balance disk wear monitoring,

- approved for operation in explosion-hazard zones – ATEX Ex I M2.

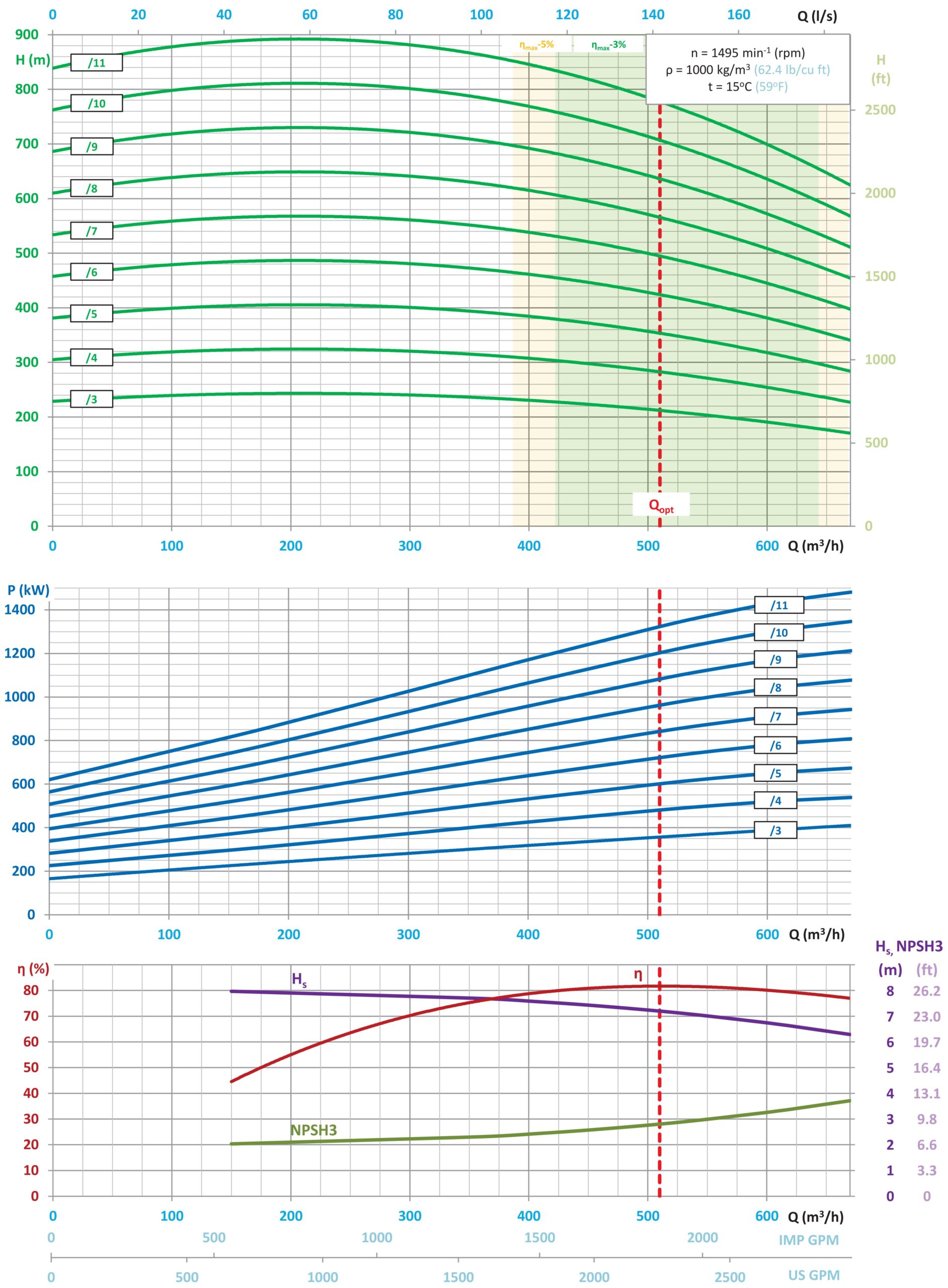

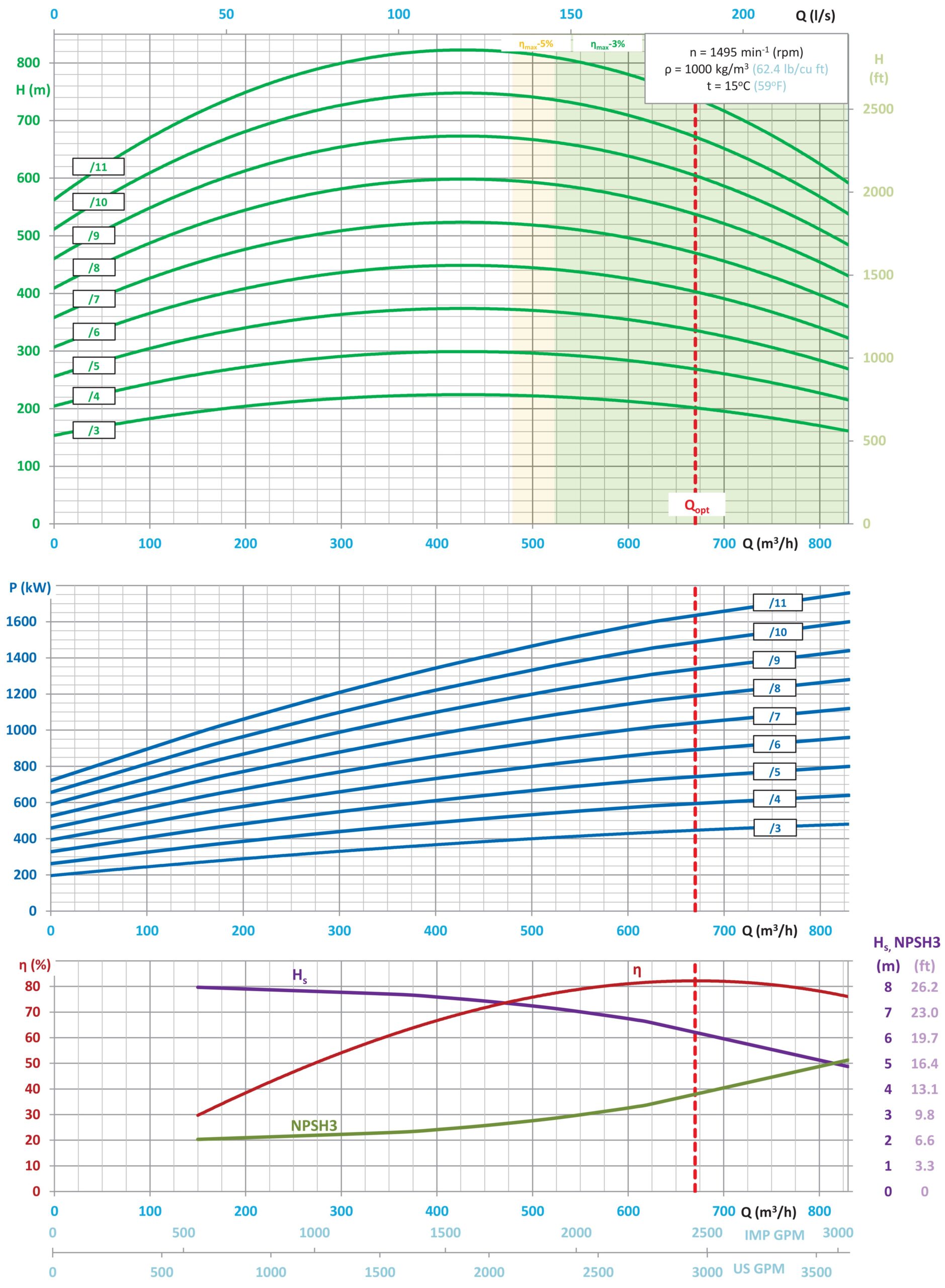

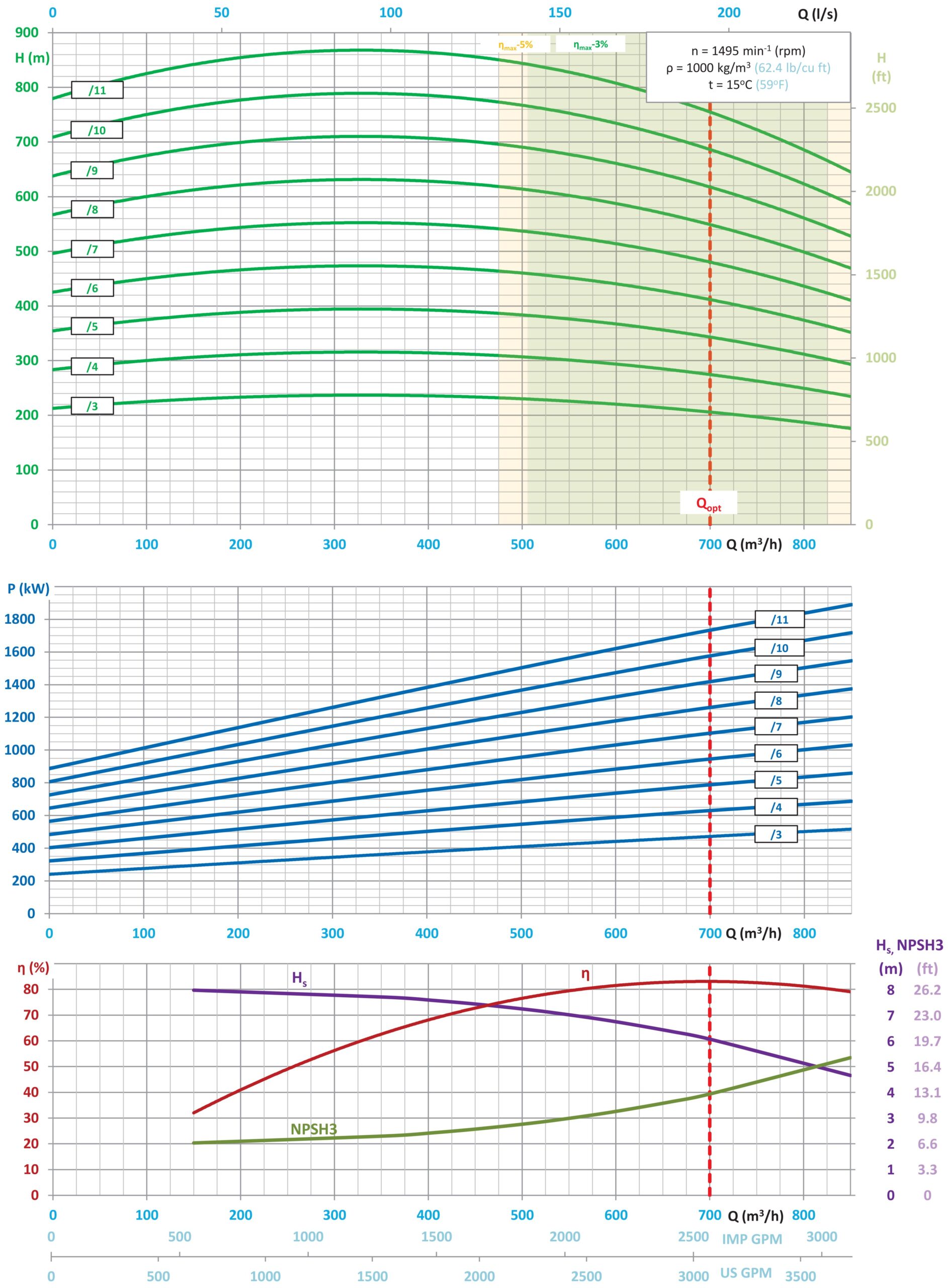

PUMP PERFORMANCE CURVE

- impeller 20mm

- H = f(Q) - lift head acc. to rate flow,

- P = f(Q) - power input acc. to rate flow,

- η = f(Q) - efficiency acc. to rate of flow,

- HS = f(Q) - allowable suction head acc. to rate of flow,

- NPSH3 = f(Q) - net positive suction head and rate of flow.

- impeller 26mm

- H = f(Q) - lift head acc. to rate flow,

- P = f(Q) - power input acc. to rate flow,

- η = f(Q) - efficiency acc. to rate of flow,

- HS = f(Q) - allowable suction head acc. to rate of flow,

- NPSH3 = f(Q) - net positive suction head and rate of flow.

- impeller 30mm

- H = f(Q) - lift head acc. to rate flow,

- P = f(Q) - power input acc. to rate flow,

- η = f(Q) - efficiency acc. to rate of flow,

- HS = f(Q) - allowable suction head acc. to rate of flow,

- NPSH3 = f(Q) - net positive suction head and rate of flow.

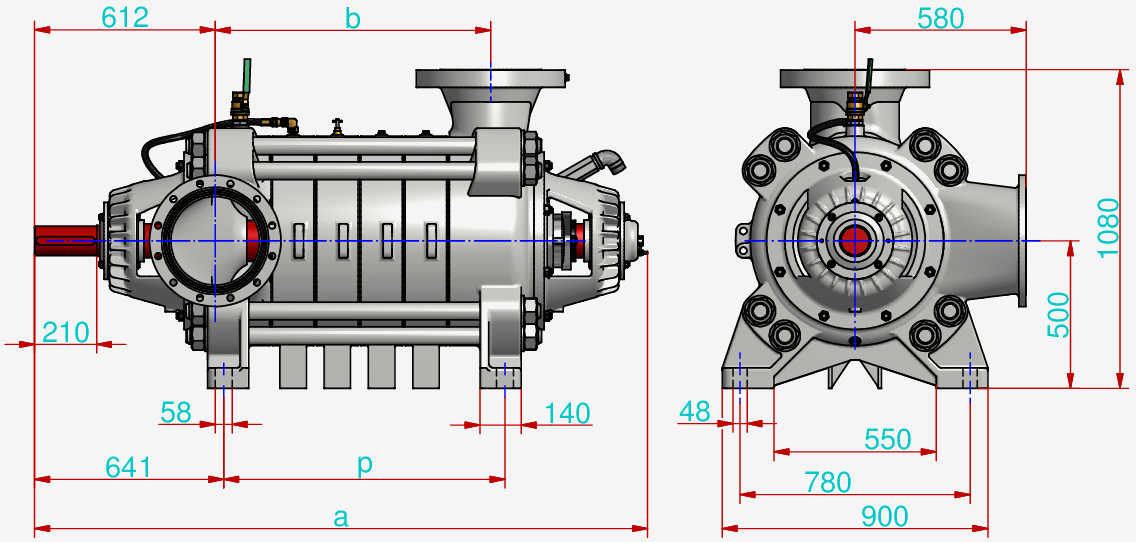

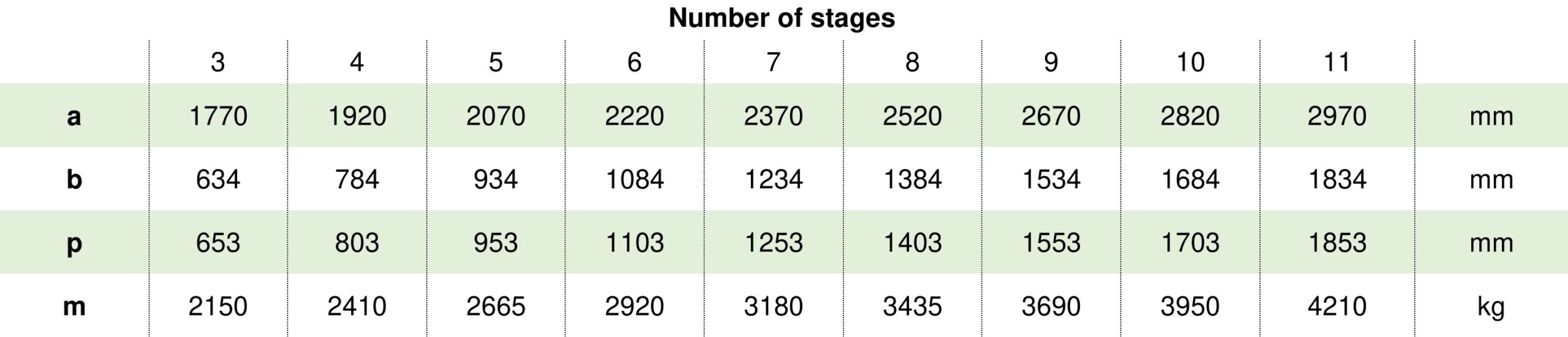

MAIN DIMENSIONS OF PUMP

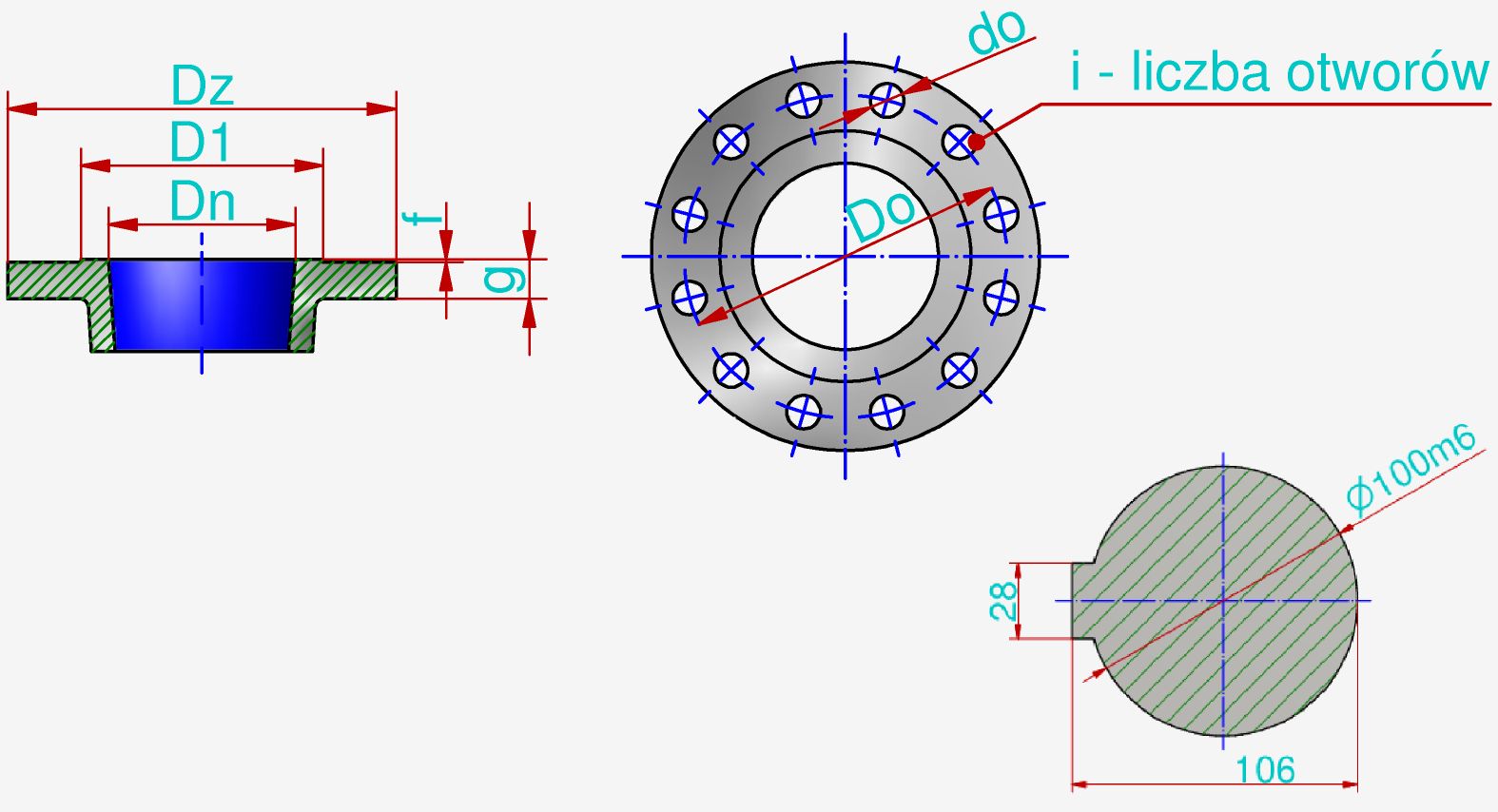

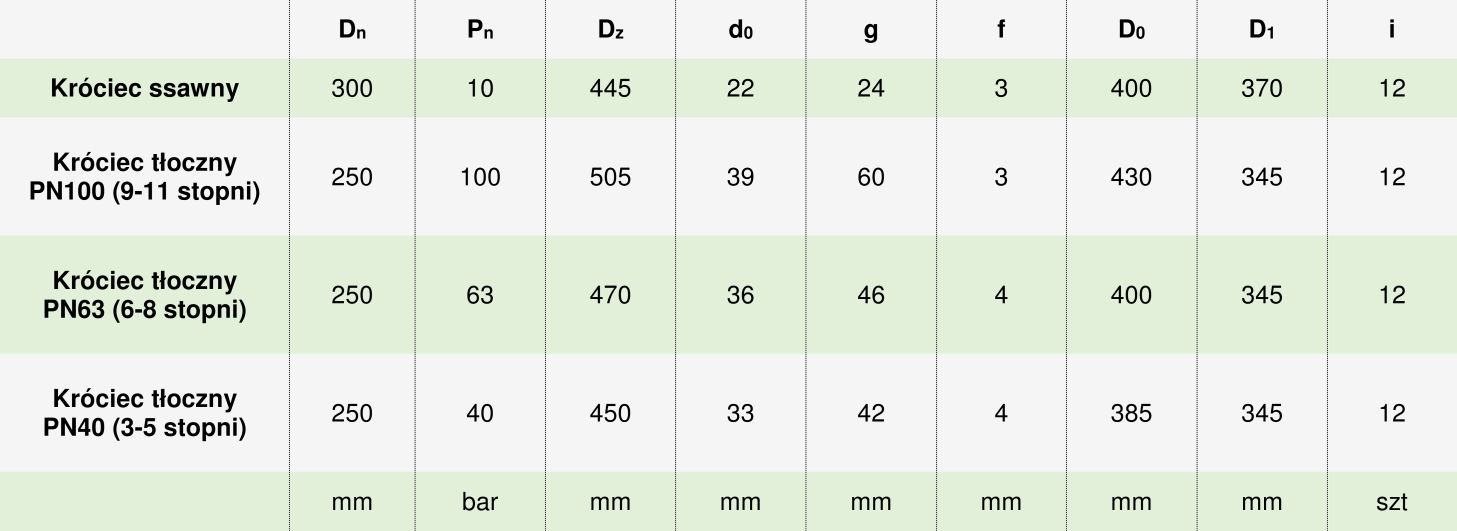

CONNECTION SIZES OF PUMP

The flanges are normally made in accordance with the standard PN-EN 1092-1 or PN-EN 1092-2.

It is possible to produce pumps with parameters different than those presented in the tables and on the graphs per agreement with the manufacturer.