WPS-200

DOWNLOAD

![]() Catalog

Catalog

![]() 2D

2D

![]() 3D

3D

SAVE TO PDF / PRINT

PUBLICATION – 2017-11-07

TYPICAL APPLICATIONS

- pumping of pure or mechanically contaminated water with solids with the grain size of up to 2 mm,

- mining – longwall and auxiliary dewatering – WPS pumps intended to replace existing medium pressure drainage pumps,

- water supply systems,

- pressure boosting,

- technological processes,

- industrial systems,

- filtration systems.

KEY ADVANTAGES

- long life ensured by the use of state-of-the-art corrosion and erosion resistant materials,

- special material execution DUPLEX especially resistant to difficult conditions,

- no water cooling of bearings required due to the appropriate design of the relief of the pump axial forces,

- silent and smooth operation,

- connection dimensions in compliance with medium pressure drainage pumps,

- inflow and suction operation,

- compact and modern design,

- maintenance-free operation with the use of mechanical sealing,

- approved for operation in explosion-hazard zones – ATEX Ex I M2.

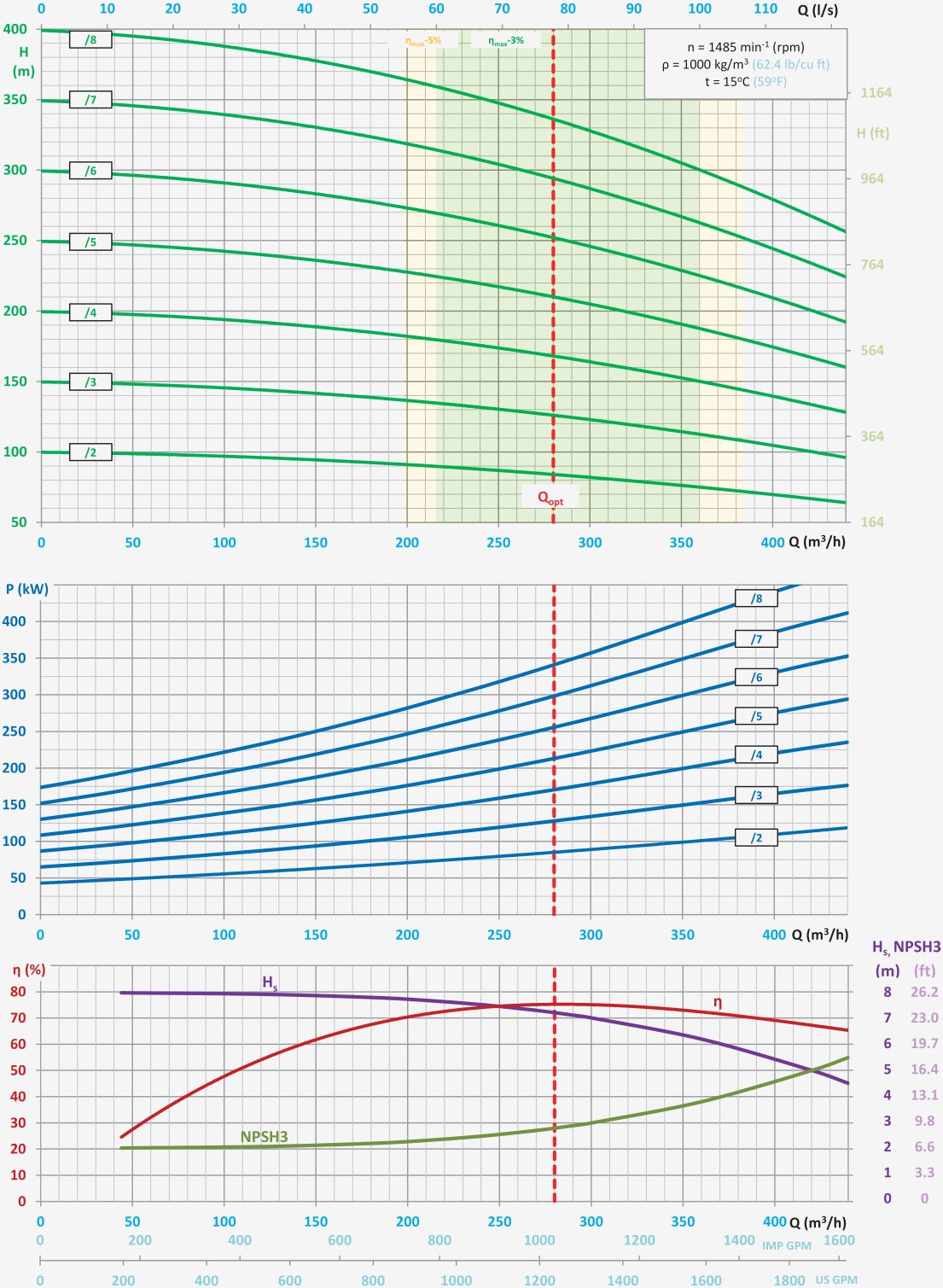

PUMP PERFORMANCE CURVE

- H = f(Q) – lift head acc. to rate flow,

- P = f(Q) – power input acc. to rate flow,

- η = f(Q) – efficiency acc. to rate of flow,

- HS = f(Q) – allowable suction head acc. to rate of flow,

- NPSH3 = f(Q) – net positive suction head and rate of flow.

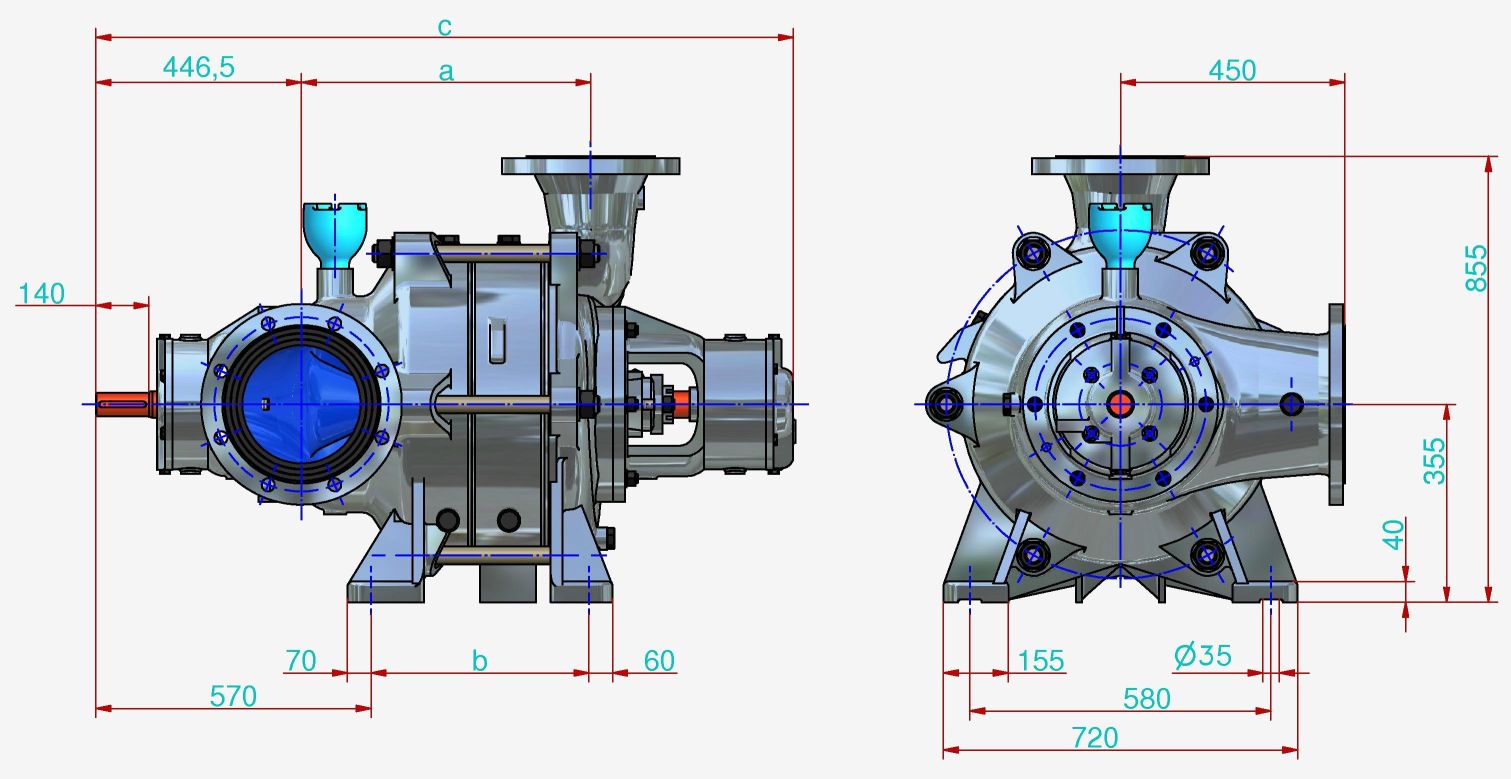

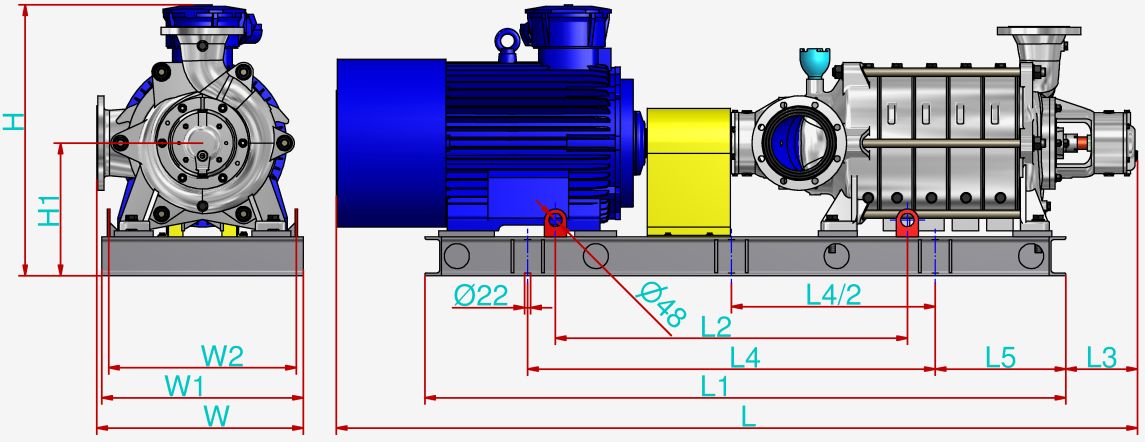

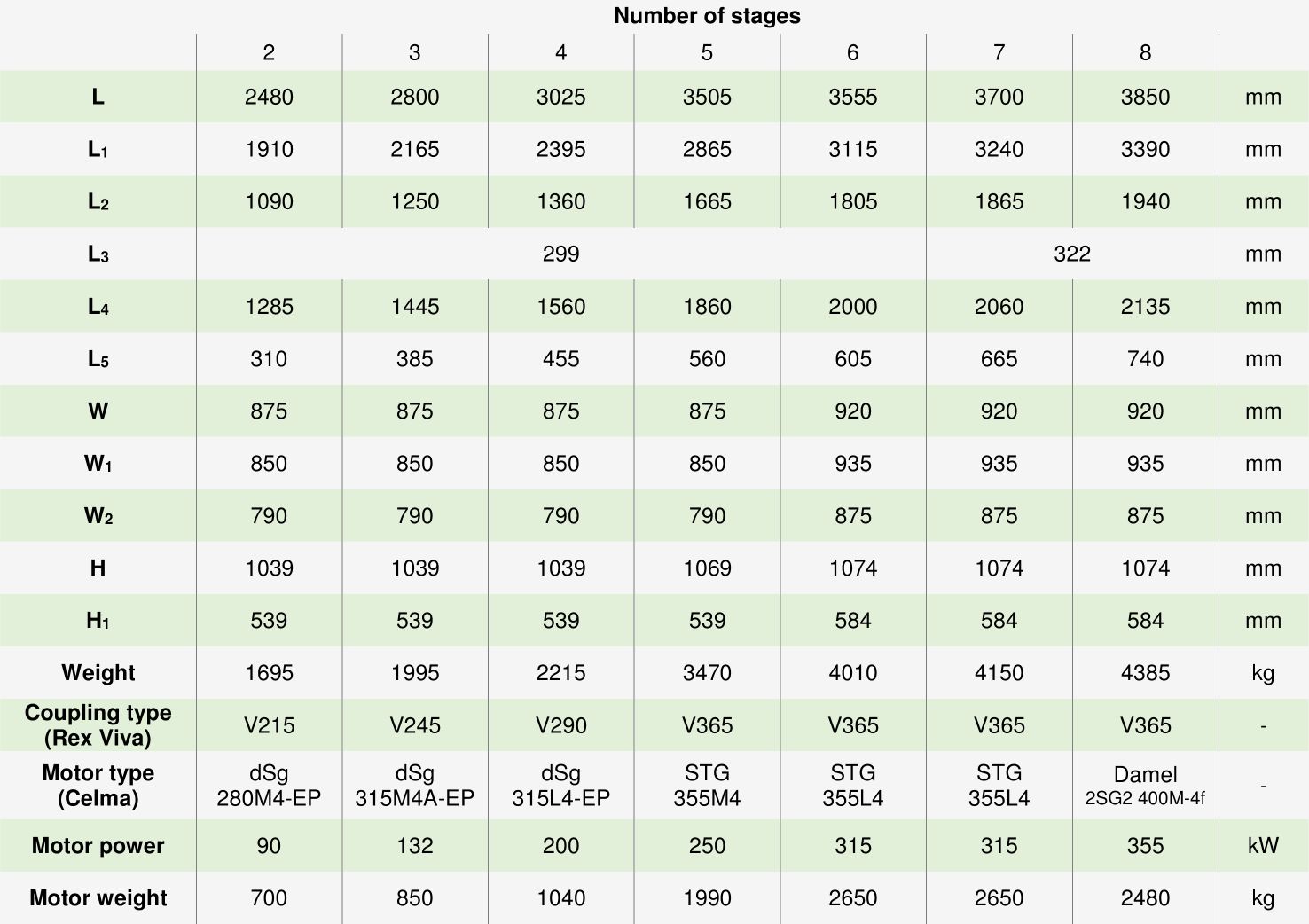

MAIN DIMENSIONS OF PUMP

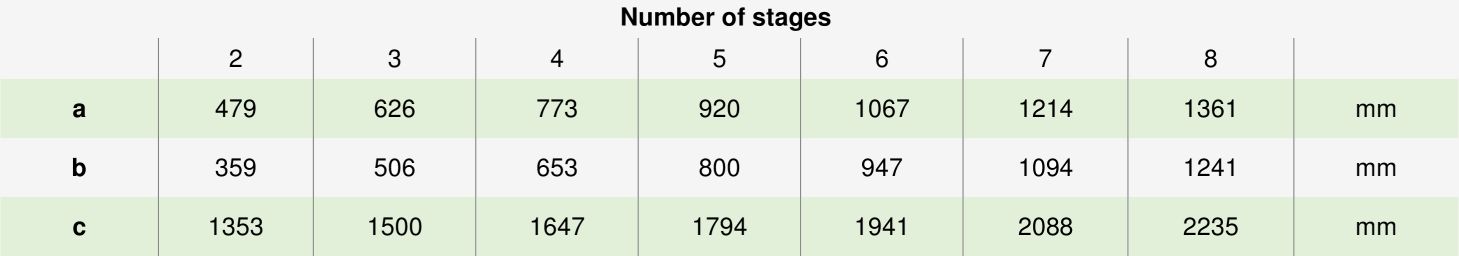

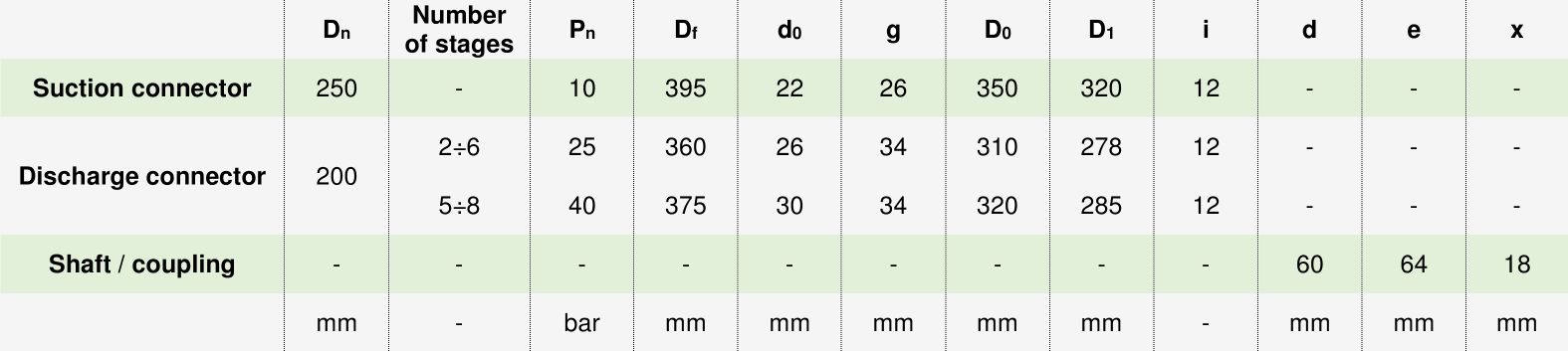

CONNECTION SIZES OF PUMP

The flanges are normally made in accordance with the standard PN-EN 1092-1 or PN-EN 1092-2.

MAIN DIMENSIONS OF PUMP UNIT

It is possible to produce pumps with parameters different than those presented in the tables and on the graphs per agreement with the manufacturer.