PHZ-100

NOMINAL OPERATION PARAMETERS AT PURE WATER PUMPING

(for the maximum rotation speed and the largest rotor)

*Pump construction enables decreasing the operational parameters by reducing the rotation speed and/or reducing the rotor’s diameter, adapting the pump to the system without choking the pump.

TYPICAL APPLICATIONS

- pumping mixtures of water and solids, with large grains and higly abrasive properties,

- pumping mixtures od water and quartz sand, ores, coal, slag, ash,

- mining – PHZ pumps intended to replace hydrotransport drainage pumps used so far,

- water supply systems,

- pressure boosting,

- technological processes,

- industrial systems,

- filtration systems.

KEY ADVANTAGES

- long life ensured by the use of state-of-the-art corrosion and erosion resistant materials,

- possibility of operation with a frequency converter,

- possibility of serial operation,

- the pumped mixture density can reach ρmax = 1700kg/m3 while pumping mixtures with a 50% content of solids in water,

- silent and smooth operation,

- connection dimensions in compliance with hydrotransport pumps,

- inflow and suction operation,

- approved for operation in explosion-hazard zones – ATEX Ex I M2.

PUMP PERFORMANCE CURVE

IN PROGRESS

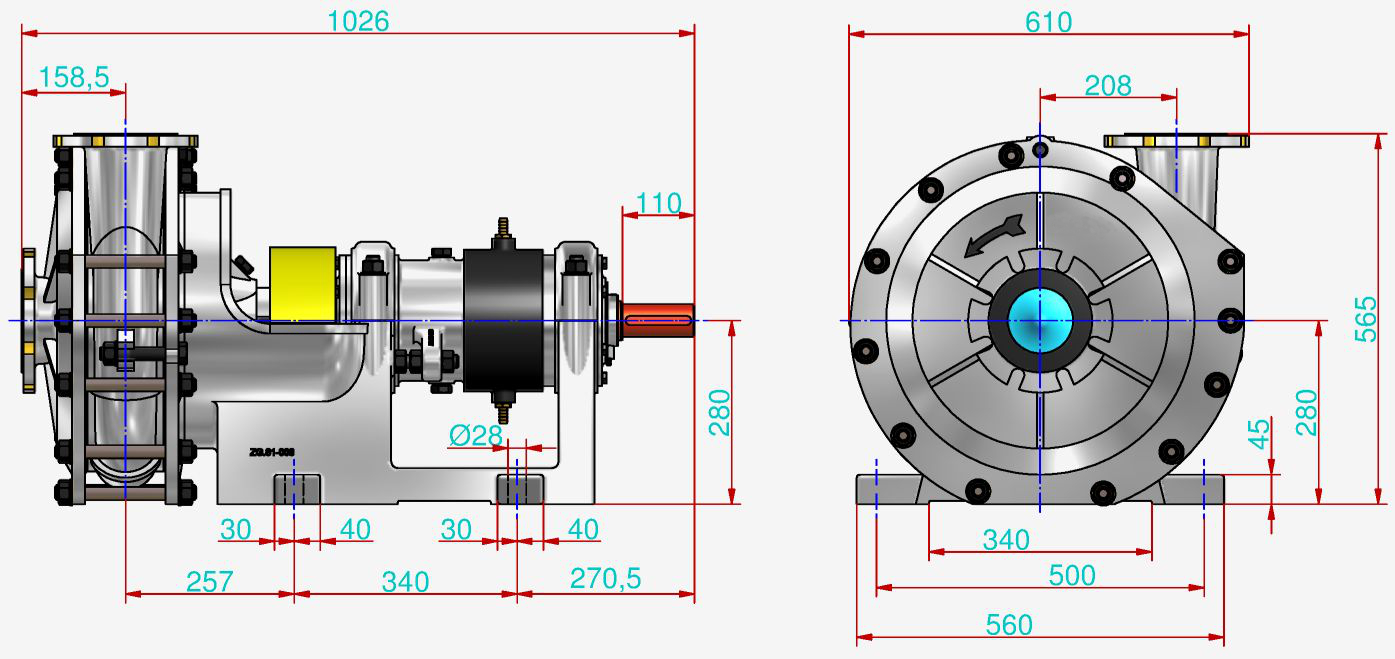

MAIN DIMENSIONS OF PUMP

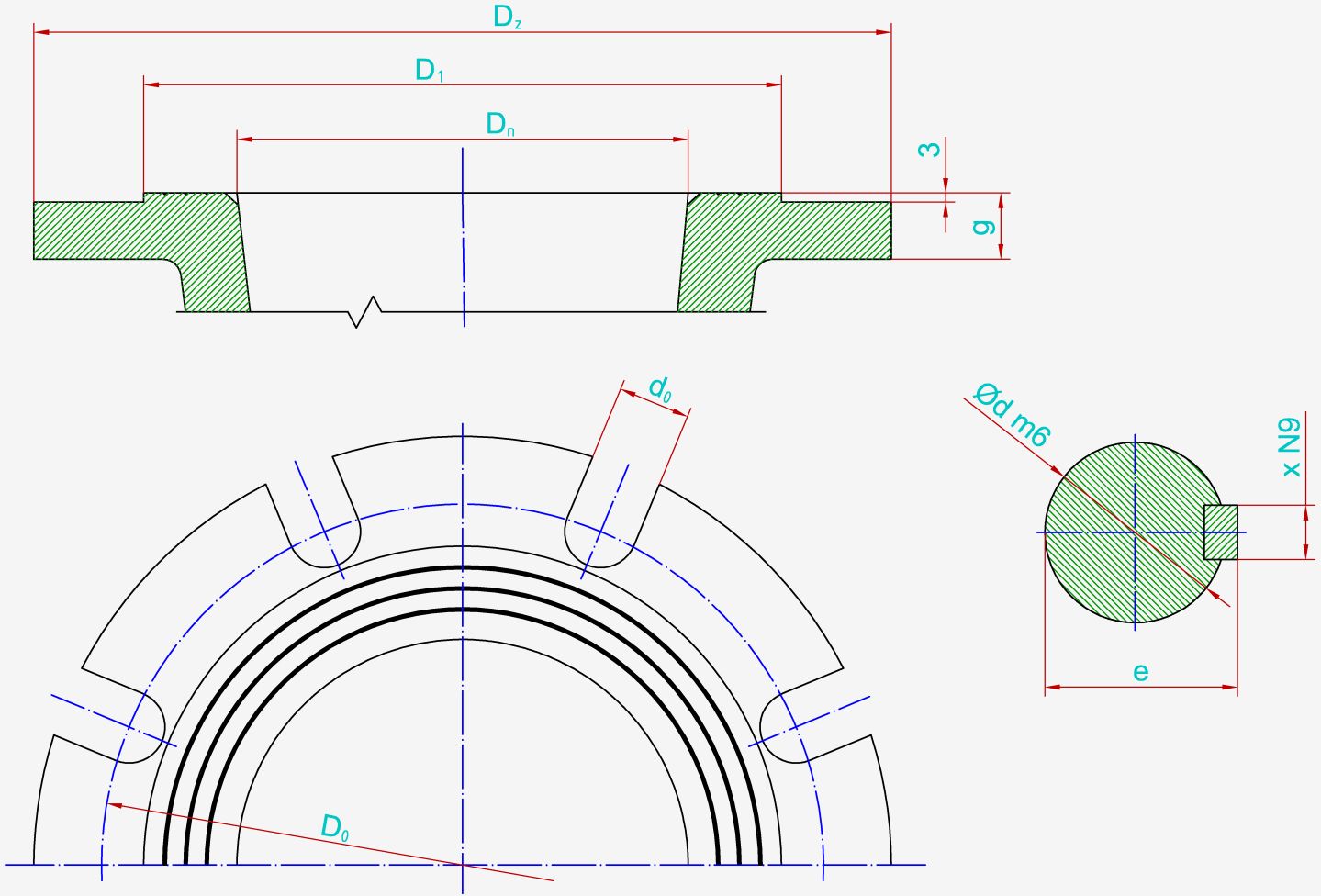

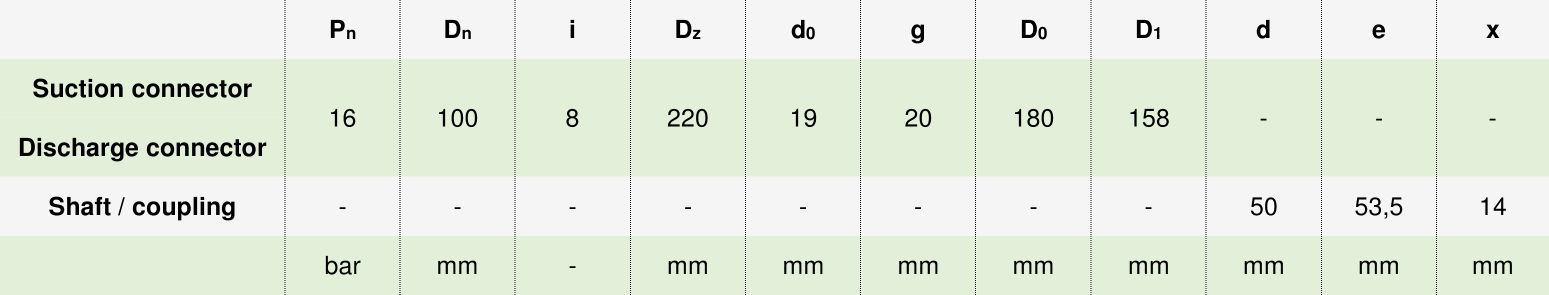

CONNECTION SIZES OF PUMP

The flanges are normally made in accordance with the standard PN-EN 1092-1 or PN-EN 1092-2.

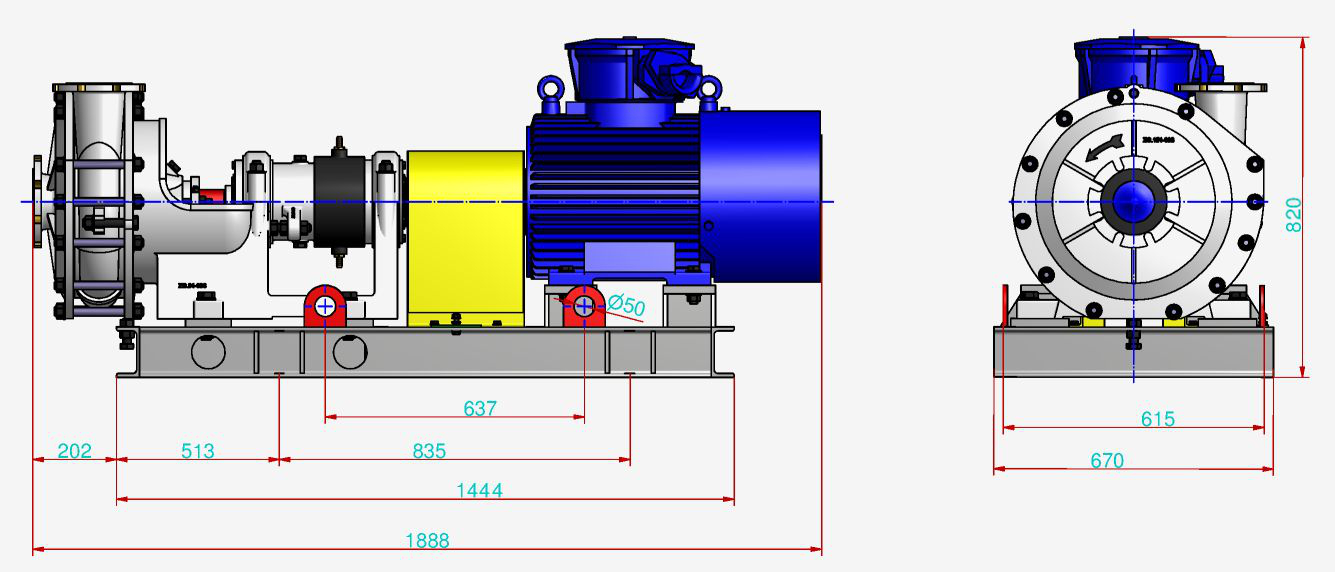

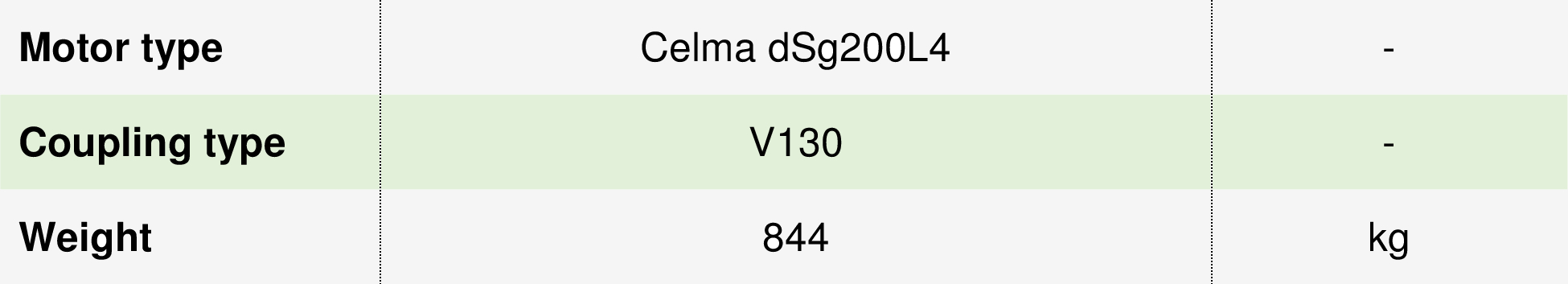

MAIN DIMENSIONS OF PUMP UNIT

It is possible to produce pumps with parameters different than those presented in the tables and on the graphs per agreement with the manufacturer.